The Benefits and Applications of Cement Head

In the oil and gas industry, cementing operations are crucial for ensuring the stability and integrity of the wellbore. One key component of these operations is the cement head, which is used to control the flow of cement during the cementing process. In this article, we will explore the benefits and applications of using a cement head in wellbore operations.

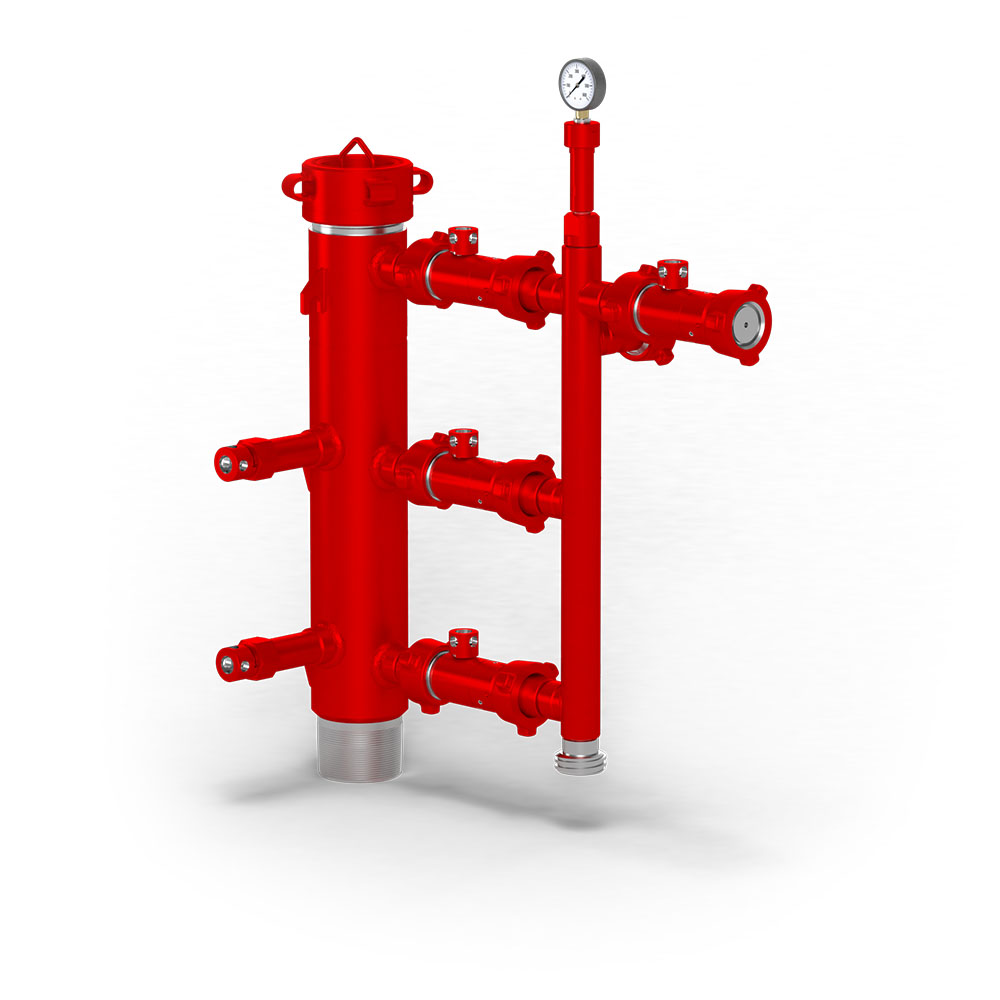

What is a Cement Head?

A cement head is a device that is used to control the flow of cement during the cementing process. It is typically installed at the top of the wellbore and is designed to provide a means of injecting the cement slurry into the wellbore. The cement head can also be used to monitor the flow of cement and to signal the end of the cementing process.

Benefits of a Cement Head

Improved Cementing Efficiency

The use of a cement head improves the efficiency of the cementing operation by providing a means of controlling the flow of cement. This ensures that the cement is properly placed in the wellbore and reduces the risk of over or under cementing.

Increased Safety

The use of a cement head improves safety during cementing operations by providing a means of monitoring the flow of cement. This ensures that the cement slurry is properly placed in the wellbore, which reduces the risk of blowouts and other safety hazards.

Reduced Contamination

The use of a cement head helps to reduce contamination by ensuring that the cement slurry is properly mixed and that it does not mix with the drilling fluids. This ensures that the cement properties are not compromised, which can lead to a stronger and more durable cementing operation.

Versatility

Cement heads can be used in a wide range of wellbore operations, including primary cementing, remedial cementing, and other cementing applications.

Applications of a Cement Head

Primary Cementing Operations

Cement heads are commonly used in primary cementing operations, where they are used to inject the cement slurry into the wellbore and to control the flow of cement.

Remedial Cementing Operations

Cement heads can also be used in remedial cementing operations, where they can be used to isolate specific zones for cementing.

Well Abandonment Operations

Cement heads can be used in well abandonment operations to seal off the wellbore and prevent fluid migration.

Conclusion

In conclusion, the use of a cement head in wellbore operations is an essential component that improves the efficiency, safety, and overall success of drilling projects. The cement head ensures proper cement placement, reduces contamination, increases efficiency, and improves safety. As such, it is a valuable tool that should be considered for any drilling project that involves cementing operations. With its versatility and wide range of applications, the cement head is an indispensable tool for successful wellbore operations.